Air quality station - Part 1

TL;DR

This is the first post of a series of posts, where I walk you through the first steps of the design of an air quality station for my home laboratory. I choose which parameters to measure, compare different sensors and choose the ones I deem appropriate, and I decide how I want to be able to operate and interact with the device.

It's a long post, as I describe the rationale behind every decision. If you're interested in the hardware/software parts, you can safely skip this one and watch out for the next part of this series.

Intro

My home lab is a cozy 5 m² room, where I spend a great deal of my days, and that's where many of my projects are conceived, developed, and built. In that same room, I often work with cleaning agents, glue, do a lot of sanding, and it also happens to be the place where my 3D printer and CNC machine fulfill their duties.

It's a small but well-ventilated room. If I open the only window in it, there's always a draft blowing in plenty of fresh air and the occasional bee.

Still, I'm aware that some of the work I do exposes me to harmful substances: solvents in glue, dust from treated wood and PCB milling, and chemicals released when my 3D printer is at work.

That's why I decided to build a small device that would monitor the quality of the air inside my home lab, and motivated me to share my experience as I make progress.

As I write this series of articles (a single one would take too long and be too boring to read), I'll walk you through the design and construction of it all: hardware, software, and even the enclosure. This is just the first iteration of the device, so please don't expect this to be the quintessential guide to building air quality monitors.

Instead, you will get a really detailed account of every step I take, while I get the chance to document everything down to the nitty-gritty aspects: the whys, hows, and the occasional pain of a wrong decision.

Towards the end, I'll write a review of what I think went awry and what can be improved. And, hopefully, some of you will reach out with some feedback.

In this first part, I'll deal with the problem statement: I'll put together a set of requirements to address the problem, and I'll set the constraints of my design. That is, I'll decide what I want my air quality station to do, what will it take to get there, and what are the tradeoffs to meet cost and performance goals.

Let's get started!

Problem statement

I want to build a simple device that gives me an idea of the quality of the air in my lab room at a reasonable cost.

So, the first question I need to answer is: what parameters can tell me how good or bad the quality of an air sample is?

And the second question is: what's a reasonable cost for a device that measures these parameters?

Which parameters?

To decide which parameters I need to measure, I'll start by getting a better understanding of how indoor air quality is defined.

Both the U.S. Environmental Protection Agency (EPA) and the European Occupational Safety and Health Administration (OSHA) publish thorough documentation [1] [2] about indoor air quality and which parameters should tell us how clean the air around us is.

Both agencies list a series of pollutants known to be found indoors. Measuring them all, though, would require both a substantial investment (some of the sensors can be expensive) and more complex hardware.

So, let's to do without measuring things like carbon monoxide and radon (which I don't expect to find in my lab), and focus on what I will most likely find.

This way, I can fail fast, learn from my mistakes, and iterate to apply those learnings to the design of a better device later on.

This brings the number of parameters down to five:

Temperature

Relative humidity (RH)

Particulate matter (PM)

Total volatile organic compounds (TVOC)

Carbon dioxide (CO2)

I'm choosing these parameters, because:

They're representative of what I want to measure - PM, TVOC and CO2 account for over 90% of the pollutants my activities will generate. Nothing I'll do in my lab will produce any carbon monoxide, sulfur or nitrogen oxides, for example, so I'm simply ruling them out for now.

Sensor cost - All five parameters can be measured cost-effectively with any of the multiple sensors available for purchase. There are also plenty of breakout boards available as well, which will make prototyping easier.

Battery-friendly sensors - There are sensors for all three parameters that can be operated at low power, or alternatively turned off or set to a low-power mode when not in use.

As for temperature and humidity measurements, they can help understand whether certain environmental conditions favour the production of pollutants. Higher temperatures, for example, may favour materials — such as plastic — to emit more TVOCs.

Now, let's delve into the reasons for why exactly these five parameters are representative of the pollutants I can expect in my lab.

Particulate matter

The term particulate matter refers to microscopic solids or liquids that are suspended in air, and that can either be byproducts of human activity, such as burning fossil fuels or mining, or natural, such as wildfires or pollen. Some of these particulates can be inhaled and, depending on their size, can lodge deep into the lungs or get into the bloodstream.

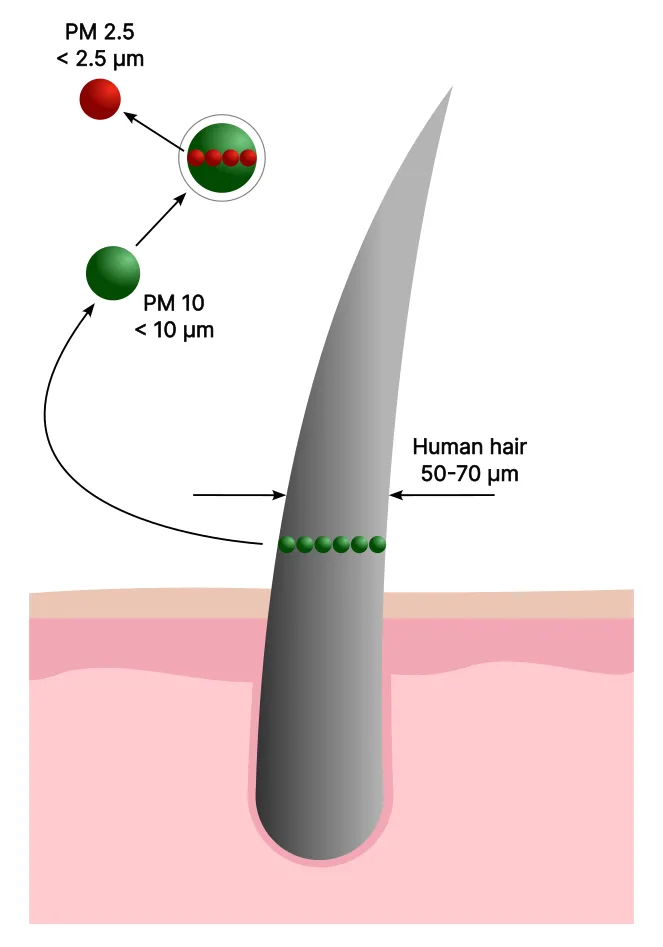

Particulate matter of sizes 2.5 and 10 micrometers compared with a human hair

Some of the things I do in my lab include milling (wood or printed circuit boards), cutting metal or wood, and 3D printing. All these activities produce particulate matter [3], which is why I want to keep an eye on the level of PMs at any point in time.

Total volatile organic compounds

Volatile organic compounds (VOCs) are organic compunds that have a high vapour pressure and low water solubility [4]. They're responsible for natural scents and perfumes, but can also be harmful solvents or by-products of industrial activity, such as toluene, trichloroethylene, and chloroform.

Detecting and measuring each of these compounds individually requires the use of complicated analysis techniques. But there are sensors that can detect them "in bulk" and alert us of their presence. These are called TVOC (total volatile organic compound) sensors.

The kind of VOCs that I'm worried about are those emitted by glues, solvents, and plastics that I normally use. Prolonged exposure to some of them can be harmful, and I want to get some sort of notice in case I need to ventilate the room.

So, an approximate measure of TVOCs can trigger an alarm and notify me if levels have reached too high a level.

Carbon dioxide

As a proud member of the Hominidae family, I breathe oxygen and exhale copious quantities of carbon dioxide. During winter, I spend long periods of time with my lab window closed, which means CO2 eventually builds up. High concentrations of carbon dioxide in air can produce fatigue and headaches [2], which I'd rather avoid.

Reasonable cost

Back to the initial questions, what is a reasonable cost?

There is probably not a single way to define what reasonable cost is. Some, if not most, of the definitions I found online [22] [23] refer to the price that a prudent person would be willing to pay. The problem I see with that definition is that it's not easy to objectively define how prudent people behave.

So, I'd like to share with you the way I like to see it. To me, a cost is reasonable when, given a need and a context, you pay a price that results in the best possible outcome.

Imagine for a moment that the slightest deviation from ideal air quality could kill you. Now you'd be more willing to spend a lot more money to get the best possible measurements. After all, what good is money for if you're dead and can't use it, right?

In reality, things are seldom this critical. In my case, reasonable means a cost that I can pay without giving up other more important things in my life, like paying my bills.

In this case, the best possible outcome is building a device that gives me a representative measure of the quality of the air I breathe in my lab, that helps me learn something along the way, and that I can pay with the money I set aside for projects.

After doing some research and having the average cost of all parts, I've decided the total cost should not exceed 200 EUR.

Requirements

Having decided which parameters I'm going to measure and what a reasonable cost is, I now need to make a few technical decisions.

Which sensors am I going to use?

To decide which sensor I will use for each parameter, I need a set of criteria. I'll split these into common criteria and specific criteria. That is, things that are common to all sensors, and things that are specific to each one.

The set of common criteria I will use are:

Ease of use — I don't want to write complex code or make difficult or complex corrections to the readings. I just want the sensor to return a value that's meaningful and straightforward to use.

Cost — With a budget of 200 EUR, sensors shouldn't exceed 70–80% of it.

I²C interface — To keep the pin count low, I'll use the I²C bus for all sensors.

Documentation — Arcane hardware with incomplete or missing documentation can be a project killer. I want well-documented sensors.

Popular — This is not mandatory, but the more people using a device, the easiest it is to find documentation and read about real-life performance of a device.

And for each sensor, the specific criteria are:

Carbon dioxide

There are two types of CO2 sensors that are both affordable and widely available: transmissive and photoacoustic nondispersive infrared (NDIR) sensors.

It's beyond the scope of this post to describe the differences between both principles of operation. You can check this [5] short but excellent explanation put together by Sensirion. And if you want more detail, this paper has an awesome description of the different NDIR sensing techniques [6].

There are plenty of transmissive NDIR sensors to choose from, but only a fraction of these are available in breakout boards ready to use. Of those, the SCD-30 from Sensirion was priced reasonably (under 60 EUR) and easy to procure.

Photoacoustic NDIR sensors are not yet quite popular. There were two options that I can easily procure: the Sensirion SCD-40/SCD-41 and the PASCO2V01 from Infineon. Again, I'm going for the Sensirion one, because it's more readily available.

Now, it's time to put these two under a stricter scrutiny:

Feature |

SCD-30 (Transmissive) [7] |

SCD-41 (Photoacoustic) [8] |

|---|---|---|

Measurement range |

✅ (400 - 10000 ppm) |

✅ (400 - 5000 ppm) |

Accuracy |

✅ ±(30 ppm + 3%MV) |

✅ ±(50 ppm + 5% rd) @ [CO2] ≤ 2000 ppm |

Dimensions |

❌ 35 x 23 x 7 mm |

✅ 10.1 x 10.1 x 6.5 mm |

Power |

❌ 10 mA average [9] |

✅ 450 µA @ 3.3V, Tsamp = 5 min [10] |

Interface |

✅ (I²C, ModBus, PWM) |

✅ I²C |

Price |

❌ EUR 50-55 |

✅ EUR 38-47 |

Comparing these sensors feature by feature:

Indoor CO2 levels can range between 400 and 2500 ppm [24], both sensors meet the requirement.

In terms of accuracy, the SCD-30 is the better option. But the SCD-41 will do just fine as well.

With a smaller footprint, the SCD-41 takes the lead.

With better low-power modes, the SCD-41 scores one more point.

The SCD-30 has more interface options, but we only need I²C.

The SCD-41 price tag is lower, which earns it another point.

With a lower cost, smaller footprint, and lower sleep power, the SCD-41 is the clear winner here.

TVOC

Most, if not all, TVOC sensors are based on the same technology, called MOx (metal oxide) or MOS (metal oxide sensor).

When exposed to certain organic chemicals, the oxide layer in these sensors changes its conductivity, which is seen as a variation in electrical current [12].

There is a large number of sensors available for measuring TVOC. I'm choosing those with affordable, easy-to-use breakout boards to begin with:

MQ-x (x = 4, 5, 135, and so on) — A series of sensors of Chinese origin that are available virtually everywhere and from multiple manufacturers.

MiCS5524 — A gas sensor from SGX Sensortech.

SGP-30 — An earlier gas sensor from Sensirion.

SGP-40 — Newer gas sensor from Sensirion.

ENS160 — A multi-gas sensor from ScioSense.

BME680/688 — A gas sensor from Bosch Sensortech that measures relative humidity, barometric pressure, ambient temperature, and (of course), VOC.

Of these, both the MQ-x and the MiCS5524 [11] sensors do not meet either the I²C interface or the ease of use criteria, and so I'm discarding them.

The SGP-30 and SGP-40 are the previous and next generation of TVOC sensors from Sensirion, respectively. The SGP-40 is easier to use: it outputs measurements as a VOC Index Signal that's easier to read, has a wider range for supply voltage, and a wider range for operating conditions, among other things [13]. Thus, I'm not considering the SGP-30.

Now, having narrowed down the choice to three sensors, let's build a decision matrix:

Feature |

SGP-40 [14] |

ENS160 [15] |

BME680 [16] |

|---|---|---|---|

Parameters |

✅ Raw, VOC Index |

✅ eCO2, TVOC, AQI-UBA |

✅ IAQ, humidity, pressure, temperature |

Dimensions |

✅ 2.44 x 2.44 x 0.85 mm |

✅ 3.0 x 3.0 x 0.9 mm |

✅ 3.0 x 3.0 x 0.93 mm |

Power |

✅ 34 µA idle, 2.6 mA |

❌ 0.01 mA idle, 24 mA |

✅ 0.015 (idle), 0.09 - 12 mA

(depends on op. mode)

|

Interface |

✅ I²C |

✅ I²C, SPI |

✅ I²C, SPI |

Compensation |

❌ External (T, H) |

❌ External (T, H) |

✅ Internal (T, H) |

Price |

✅ EUR 14-18 (BB), EUR 9 (S) |

✅ EUR 19-21 (BB), EUR 10 (S) |

✅ EUR 18-21 (BB), EUR 10 (S) |

The internal humidity and pressure sensors in the BME680 and the possibility to use them for internal compensation make it the clear winner.

The SGP-40 and ENS160 are both great sensors. But the lack of internal temperature and humidity sensors place them behind the BME680. As a bonus, the BME680 also features a barometric pressure sensor.

Particulate matter

Choosing a PM sensor is going to be simpler. The candidates I'm reviewing are:

SPS-30 — PM sensor from Sensirion

IH-PMC-00x (x = 1, 2) — PM sensor series from Honeywell

PMSA003I — PM sensor from Plantower [27]

I've found the Plantower sensors to be lacking in a number of ways. The datasheets fall under the arcane category: difficult to find and lacking information on what the sensor capabilities are. And the reviews [28] [29] aren't great, either. That is why I decided to focus on the Sensirion and Honeywell sensors.

The IH-PMC-00x sensors from Honeywell and the SPS-30 from Sensirion are very similar:

Feature |

SPS-30 [17] |

IH-PMC-00x [18] |

|---|---|---|

Measurement range |

✅ 0 - 1000 µg/m³

0 - 3000 #/cm³

|

✅ (0 - 1000 µg/m³) |

Accuracy (PM2.5) |

✅ ±5 [μg/m3 + 5 % m.v.] |

✅ ±10 mg/m³ (0 - 100 µg/m³),

±10% M.V. (100 - 1000 µg/m³)

|

Dimensions |

✅ 40.6 x 40.6 x 12.2 mm |

✅ 49.0 x 35.1 x 10.8 mm |

Power |

✅ 38 µA (sleep), 55 mA (meas) |

✅ 150µA (sleep), 50 mA (meas) |

Interface |

✅ I²C, UART |

✅ I²C, UART |

Price |

✅ USD 35-50 |

✅ USD 36-42 |

Both are strong candidates, but with a lower sleep current (38µA vs 150µA), a larger community building with it, and readily available from a merchant in the EU, the SPS-30 was the clear winner.

How am I going to interact with the device?

This is it. I know which sensors I'm going to use, so now it's time for me to focus on what my user experience (UX) will look like.

I want to keep this first version of the prototype simple, so I'm taking the decision of limiting the ways in which I can interact with it:

There will be no buttons or keyboards. — All interaction should go through an app.

There should be more than one debugging interface. — If I brick it, I should be able to fix it quickly.

There will be a screen with minimal status indicators. — I want to be able to quickly get a glimpse of the device's status. It will also let me measure the power consumption of a screen.

I also want to be able to use this device anywhere without the need to plug it in for power or communications. Therefore:

The device will be battery operated and rechargeable.

The device should connect to a wireless network.

Connectivity

I'll use my phone and my laptop to interact with the device and I want it to stream data periodically to the cloud. I've already said I want the device to connect to a wireless network, so the simplest choice will be Wi-Fi.

I may add Bluetooth® in a future iteration, but it's not among my priorities right now.

Data (presenting & storing)

I don't want to just display the measurements. I want to be able to:

Stream the data to a cloud-based backend in near real time.

Have a bidirectional communication channel between the device and my backend.

Support certificate-based client authentication.

Quickly retrieve near real-time data from my phone or laptop.

Store historical data indefinitely for analysis.

To implement points 1, 2, and 3, I'm going for MQTT. The alternative here would be WebSockets, but the implementation would be more complex, expensive, and would have a larger firmware footprint.

For points 4 and 5, I'm going to use AWS cloud services.

I'm leaving software design decisions for a later stage, and I'll discuss them in detail in future posts.

What microcontroller will I use?

As to the microcontroller, I'm making a decision based on the contents of my parts box.

I'm using a couple of ESP32-C3-WROOM-02-H4 [30] modules I bought some time ago, which fit the bill quite nicely: they feature Wi-Fi, a hardware I²C interface, a 4 MB Quad SPI flash, and a 160 MHz single-core microprocessor.

Next steps

Now that I've gathered and documented all requirements, I can start working on the electronics. Stay tuned for part 2 of this series!

(2024-02-25) Update — Part 2 is here!